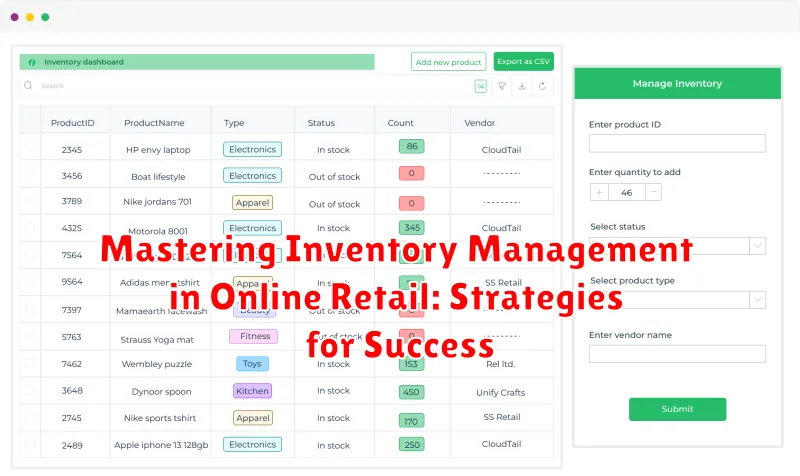

Inventory management is a crucial aspect of success in the competitive landscape of online retail. Effectively managing your inventory can significantly impact your bottom line, affecting everything from customer satisfaction to profitability. This article, “Mastering Inventory Management in Online Retail: Strategies for Success,” delves into the key strategies and best practices that will empower you to optimize your inventory control, minimize costs, and maximize your sales potential in the dynamic world of e-commerce. Understanding the nuances of online retail inventory management is essential for anyone looking to thrive in this ever-evolving market.

From forecasting demand and optimizing warehouse operations to implementing robust inventory tracking systems and exploring cutting-edge technologies, this comprehensive guide will equip you with the knowledge and tools necessary to master the art of online retail inventory management. Whether you are a seasoned e-commerce entrepreneur or just starting your online retail journey, this article will provide valuable insights and actionable steps to streamline your operations, reduce holding costs, prevent stockouts, and ultimately, achieve sustainable growth and success in the competitive world of online retail.

What is Inventory Management and Why is it Important?

Inventory management is the process of overseeing and controlling the ordering, storage, and use of inventory. This encompasses the entire journey of a product, from acquisition to sale, including raw materials, work-in-progress, and finished goods. For online retailers, this means effectively managing stock across potentially multiple warehouses, fulfillment centers, and even physical store locations if applicable.

Effective inventory management is crucial for the success of any online retail business. Properly managing inventory directly impacts profitability, customer satisfaction, and operational efficiency.

Poor inventory management can lead to several issues, such as stockouts resulting in lost sales and dissatisfied customers. Conversely, overstocking ties up valuable capital and increases the risk of obsolescence and storage costs. Efficient inventory management strives to find the ideal balance between meeting customer demand and minimizing holding costs.

Key Components of Effective Online Retail Inventory Management

Effective online retail inventory management hinges on several key components working in harmony. Accurate demand forecasting is crucial, enabling businesses to anticipate customer needs and stock accordingly, minimizing stockouts and overstocking. Real-time inventory tracking provides visibility into stock levels across all locations, ensuring accurate data for decision-making.

Strategic supplier management plays a vital role. Building strong relationships with reliable suppliers ensures timely deliveries and consistent product quality. Efficient warehouse management, including optimized layout and streamlined processes, is essential for swift order fulfillment.

Robust order management is another crucial element. This includes efficient processing, tracking, and fulfillment of customer orders. Lastly, returns management needs to be seamless. A clear return policy and efficient processing minimize losses and maintain customer satisfaction.

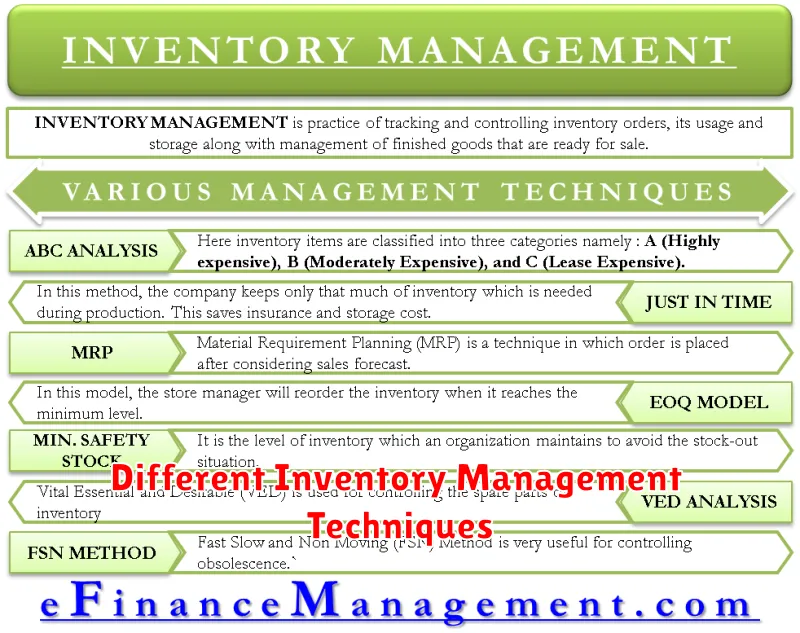

Different Inventory Management Techniques

Several techniques can be employed to effectively manage inventory in online retail. Choosing the right method depends on the specific business model, product type, and resources available.

Just-in-Time (JIT) Inventory

This technique aims to minimize inventory holding costs by receiving goods only as they are needed for production or sale. JIT requires accurate demand forecasting and reliable suppliers. It is suitable for businesses with predictable demand and short lead times.

First-In, First-Out (FIFO)

FIFO assumes that the oldest inventory is sold first. This method is particularly important for perishable goods or products subject to obsolescence. It helps minimize losses due to expiration or outdated inventory.

Last-In, First-Out (LIFO)

With LIFO, the newest inventory is sold first. While this method can be beneficial for tax purposes during periods of inflation, it may not be the most effective for managing perishable or quickly evolving products.

Dropshipping

Dropshipping eliminates the need for holding any inventory. When a sale occurs, the retailer purchases the product from a third-party supplier who then ships it directly to the customer. This method minimizes upfront investment but can result in less control over order fulfillment.

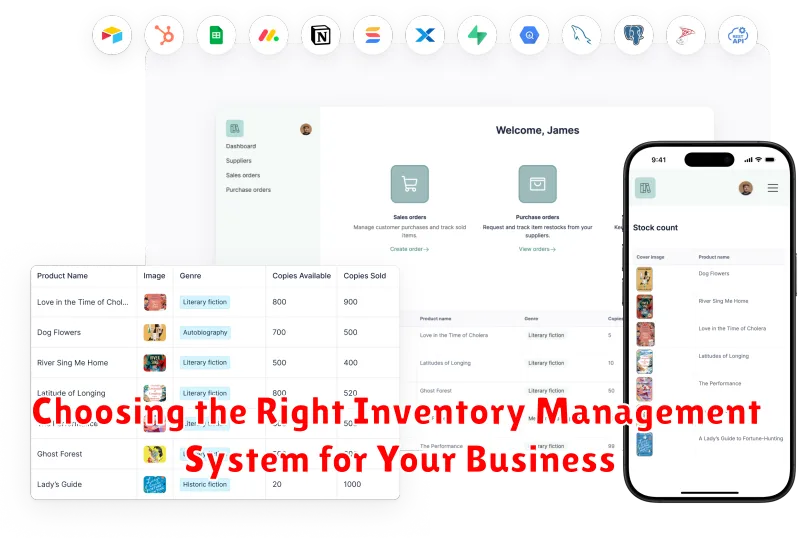

Choosing the Right Inventory Management System for Your Business

Selecting the appropriate inventory management system is crucial for streamlining operations and maximizing profitability. The right system will depend on the specific needs and scale of your online retail business. Consider these factors when evaluating different systems:

Key Features to Consider

- Real-time Tracking: Accurate, up-to-the-minute inventory data is essential.

- Sales Channel Integration: Seamlessly connect with your online marketplaces and e-commerce platforms.

- Order Management: Automate order processing and fulfillment workflows.

- Reporting and Analytics: Gain insights into sales trends, inventory performance, and other key metrics.

- Scalability: Choose a system that can grow with your business.

Types of Inventory Management Systems

Inventory management systems range from basic spreadsheets to sophisticated software solutions. Some common types include:

- Spreadsheet Software: Suitable for very small businesses with simple inventory needs.

- Standalone Inventory Management Software: Offers more features and functionality than spreadsheets, often at a reasonable cost.

- Enterprise Resource Planning (ERP) Systems: Comprehensive solutions that integrate inventory management with other business functions.

- Cloud-Based Inventory Management Systems: Provide accessibility and flexibility, often with a subscription-based pricing model.

Forecasting Demand and Optimizing Inventory Levels

Accurate demand forecasting is crucial for successful inventory management. Predicting future demand allows businesses to proactively adjust inventory levels, minimizing storage costs while ensuring sufficient stock to meet customer orders. Several factors influence demand, including seasonality, market trends, and promotional activities.

Analyzing historical sales data is a fundamental step in forecasting. Identifying patterns and trends in past sales can provide valuable insights into future demand. Statistical methods, such as time series analysis, can be employed to extrapolate past trends and generate forecasts.

Optimizing inventory levels involves finding the balance between meeting customer demand and minimizing holding costs. Safety stock acts as a buffer against unexpected demand spikes or supply chain disruptions. Calculating the appropriate safety stock level requires considering factors such as lead time and demand variability.

Regularly reviewing and adjusting forecasts is essential. Market conditions can change rapidly, impacting demand. Staying informed about industry trends and monitoring competitor activities can help refine forecasts and ensure inventory levels remain optimized.

Managing Inventory Costs and Minimizing Losses

Effectively managing inventory costs is crucial for profitability in online retail. Holding costs, which include storage, insurance, and potential obsolescence, can significantly impact the bottom line. Minimizing these costs requires a strategic approach.

Demand forecasting plays a vital role. Accurate predictions of future demand allow for optimized stock levels, reducing the risk of overstocking and minimizing storage costs. Regularly reviewing and adjusting safety stock levels is also essential to balance the risk of stockouts against excessive holding costs.

Inventory turnover is a key metric to monitor. A higher turnover rate indicates efficient inventory management and minimizes the risk of losses due to obsolescence or spoilage. Strategies like First-In, First-Out (FIFO) can help prioritize the sale of older inventory.

Minimizing losses also involves addressing shrinkage, which encompasses theft, damage, and administrative errors. Implementing robust inventory control procedures, including regular cycle counting and thorough receiving processes, can help mitigate shrinkage and maintain accurate inventory records.

Integrating Inventory Management with Other Business Processes

Effective inventory management doesn’t exist in isolation. It’s a crucial component intertwined with other core business processes. Seamless integration is key to maximizing efficiency and profitability.

Integrating with Sales and Marketing: Real-time inventory data informs marketing campaigns and sales strategies. Knowing what’s in stock prevents promoting unavailable items and allows for dynamic pricing adjustments based on availability.

Connecting with Procurement and Suppliers: Automated purchase orders triggered by low stock levels streamline the replenishment process. Integration facilitates efficient communication with suppliers, ensuring timely deliveries and minimizing stockouts.

Synchronization with Order Fulfillment and Shipping: Accurate inventory data is fundamental to efficient order processing and shipping. Knowing precisely what’s available and where it’s located enables swift and accurate fulfillment, minimizing errors and delays.

Integration with Accounting and Finance: Inventory represents a significant asset. Connecting inventory management with accounting systems ensures accurate valuation of inventory, tracks costs, and facilitates accurate financial reporting.

The Future of Inventory Management in Online Retail

The future of inventory management in online retail is poised for transformative change, driven by emerging technologies and evolving consumer expectations. Artificial intelligence (AI) and machine learning (ML) will play increasingly crucial roles, enabling more accurate demand forecasting and automated replenishment. This will lead to optimized stock levels, minimizing storage costs and reducing waste from overstocking or stockouts.

Blockchain technology offers enhanced transparency and traceability throughout the supply chain. This allows for improved product authenticity verification and streamlined logistics processes, contributing to greater efficiency and customer trust.

The rise of autonomous robotics and warehouse automation will further revolutionize inventory handling. Automated guided vehicles (AGVs) and robotic picking systems can optimize warehouse operations, improving speed and accuracy while reducing labor costs.

Personalized experiences are also becoming increasingly important. Inventory management systems will need to adapt to support on-demand manufacturing and customized product offerings, catering to individual consumer preferences and enabling faster turnaround times.